December 2015

In This Issue

Message from Assistant Secretary Jay Williams

At EDA we support this strategic focus by working with our partners across the nation to make key long-term investments in the foundation of America’s economic growth - investments in people through skills training; investments in innovation and entrepreneurship; and investments in the country’s physical and digital infrastructure. As we mark our 50th Anniversary, we are proud of all of the great work that the agency and our partners have accomplished. In 2015, EDA supported the Department’s strategic plan through its approximately 620 investments totaling approximately $250 million. Through these catalytic investments and the partnerships, we have helped to set the path forward for economic development. Some of our highlights from 2015 are spotlighted below. We thank you for your partnership in 2015! We certainly have a lot to be proud of, and we look forward to continuing to advance America’s competitiveness in 2016. Jay Highlight: EDA: A Year in Review2015 marked EDA's 50th anniversary! Taking the time to reflect on everything EDA has accomplished helps us showcase the power of economic development and reminds us of the importance of supporting regional collaboration and focusing on innovation to create jobs! Listen to U.S. Secretary of Commerce Penny Pritzker Commemorate EDA's 50th Anniversary (video)  Secretary Pritzker with EDA staff for EDA's 50th anniversary celebration.

Click here to read moreSuccess Stories GE facility in Asheville, NC

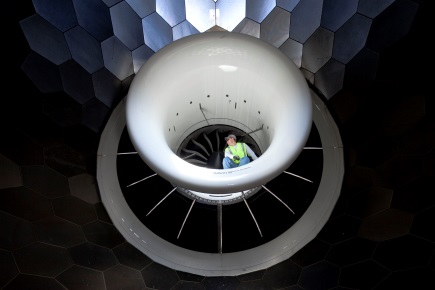

Ashville, NC (ATRO) EDA University Center Partners with GE to Support Manufacturing of Aircraft EnginesSuccessful manufacturing is predicated upon innovation and implementation of new technologies that will support long-term competitiveness. While this is true in all industries, it is particularly true in aviation manufacturing. Increased pressures by consumers for engines that are fuel efficient and more powerful have led GE, a leader in aircraft engine manufacturing, to develop the new LEAP aircraft engine. This fourth generation aircraft engine is the most technologically advanced engine that the firm has ever produced and is stimulating significant investment in a number of GE manufacturing plants across the country to develop, assemble, and test parts for the new engine. As GE ramps up to begin full production of the new engine in 2016, the company has been examining how they can streamline operations to meet the growing demand beginning on day one. At the GE facility in Asheville, NC, engineers and workers have been examining how the rotating seals and blades of the LEAP engine could be manufactured more efficiently, which will enable the company to manufacture more engines in a manner that is safer for employees. Currently, these components require manual deburring, or the removing of sharp metal edges to reduce friction and eliminate stress points in the engine. This process can take a skilled technician upwards of nine hours of extremely repetitive motion for a single rotating seal. In order to meet demand by customers and fulfill preorders for the LEAP engine efficiently, the process for deburring these components needs to be significantly reduced. As GE engineers at the Asheville plant have been considering this challenge, they partnered with Western Carolina University's (WCU) Center for Rapid Product Realization, a University Center supported by the U.S. Economic Development Administration (EDA), to secure a team of engineering students to design and build an adaptive, automated system to deburr and contour the edges of the GE90-115B Forward Outer Seal. Through this partnership, the team has designed and programmed a robotic arm to automate the deburring process and has demonstrated how the technology could be utilized in the GE facility. |

|

|

|||

Jorge Ayala Named New Director of EDA’s Austin Regional OfficeJorge Ayala has been named the new Regional Director of the Austin Regional Office. In this new role, Jorge will oversee infrastructure development, capacity building and economic adjustment assistance with an active portfolio of over $300 million in grants. Jorge has been a dedicated member of team EDA for over 20 years – proving tremendous support to the agency and our stakeholders. Prior to assuming this new role, he worked in several capacities, including Acting Regional Director, Area Director, Director of Operations Management, and Project Engineer. In 2003, he received the U.S Department of Commerce Silver Medal Award for his work with the Economic Development District funding program. Jorge holds a Bachelor of Science in Mechanical Engineering from Texas A & M University – Kingsville and a Master of Science in Engineering Management from the University of South Florida. HANNOVER MESSE: Meet the Entire World of Industrial Technology at One Trade ShowSince 1947, there have been plenty of advances in industrial technology. But one thing that has stayed the same is that HANNOVER MESSE remains the premier trade event to learn about the latest trends, the top companies, and the most innovative solutions in the sector. That said, 2016 will be a singular year in the history of the 68-year-old trade event. For the first time, the United States is the Partner Country for HANNOVER MESSE, and that means more opportunity and greater exposure for U.S. companies and economic development organizations (EDOs). U.S. companies and EDOs that join HANNOVER MESSE as exhibitors will get a prime location exhibiting in the U.S. Pavilions, so they can showcase their goods, services, and investment opportunities to the largest possible audience. What’s more, the U.S. Commercial Service and SelectUSA teams will be on hand to make sure each company or EDO makes the most out of the show. Visit trade.gov to learn more about the opportunities for your company or EDO at HANNOVER MESSE. Share Your StoryWe want to highlight your economic development success stories. Please tell us your story and let us know how EDA partnered with you! Planning for a More Resilient FutureA Guide to Regional Approaches - The National Association of Development Organizations (NADO) with help from EDA has created a comprehensive guide to help Regional Development Organizations (RDO’s) improve regional resilience. Department of Labor Launch $100 Million TechHire Grant CompetitionThe U.S. Department of Labor’s Employment and Training Administration has announced the availability of approximately $100 million in grant funds for the TechHire partnership and grant program. The program is designed to provide individuals with the skills they need and connect them to well-paying, middle- and high-skilled, and high-growth jobs across a diversity of H-1B industries. These grants will pilot and scale-public private partnerships among the workforce investment system, education and training providers and business related non-profit organizations. For more information please see the White House fact sheet and the funding opportunity notice on Grants.gov. NADO to host webinar on issues communities face when a nuclear plant closesOn December 9 from 11 a.m. to 12 p.m. ET, the National Association of Development Organizations (NADO) will host a webinar to highlight issues communities face when a nuclear plant closes. The webinar will introduce participants to the closure and decommissioning regulatory process which currently lacks local influence in closure and decommissioning decision-making. Register for the webinar. |

At the Department of Commerce, our strategic plan provides us with a clear mission: to grow trade and investment, support innovation, provide environmental intelligence, unlock our data for the benefit of businesses and the public, and to deliver our services with operational excellence.

At the Department of Commerce, our strategic plan provides us with a clear mission: to grow trade and investment, support innovation, provide environmental intelligence, unlock our data for the benefit of businesses and the public, and to deliver our services with operational excellence.